The Calibre® LFD™ design checking tool performs three important tasks:

- Gathers data about how the design will print at a range of conditions (such as dose, focus, and mask bias), not just at the optimal settings.

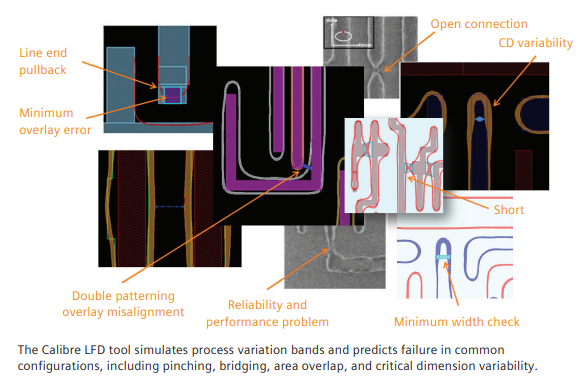

- Predicts specific failures or potential yield inhibitors.

- Assigns a manufacturability score to each portion of the design, reflective of how well that portion will manufacture given the specific process window.

Features and Benefits:

- Improves design robustness, product reliability, and manufacturing yield

- Minimizes feature variability and sensitivity to manufacturing process variations.

- Results are presented in user-friendly DRC-style that can be classified and sorted within the

- design environment.

- Model-based hints and results comments guide designers through layout improvements.

- Part of the Calibre Design for Manufacturing solution, which also includes analysis, enhancement, and diagnostics for design, manufacturing, and test areas.

- Lithography effects are simulated using product-proven RET recipes and process models.

- Foundry-supplied LFD process kit predicts and captures areas of potential design failure related to manufacturing process conditions.

- Identifies issues and provides fixing hints to the designer for optimized layout modifications.

- DVI data helps designers choose the layout configuration that is most robust against process variation.

- Easily integrated into the design flow for interactive and iterative processes.

- Fully integrated with the Calibre platform, popular layout environments, and industry-standard