Features and Benefits

- Report card guides you to specific check results for quick hotspot and violation analysis

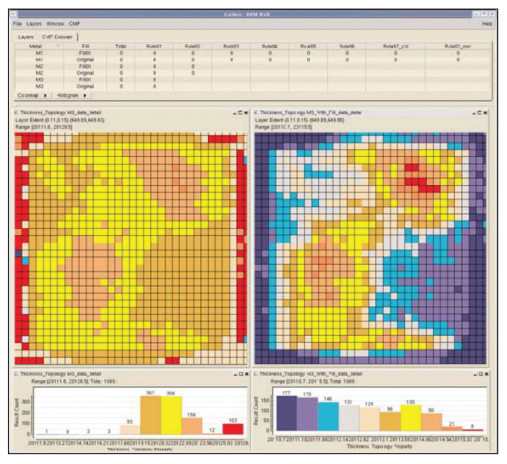

- Color maps and histograms provide global view of CMP impact on design

- Automatic fill optimization combines planarity analysis with precise fill optimization to achieve desired results while minimizing fill shapes

- Tight integration with Calibre xRC™ drives extremely accurate circuit simulations

- Customized CMP models can be developed in-house using Calibre® WorkBench™

- Ease of use: Use one menu to set up and execute simulations, analyze results and perform fill and extract operations

- Cost effective: Use customized simulation models in-house and modify when and as needed

- Control variability: Minimize fill shapes while still meeting planarity goals

- Reduce time to market – Combine CMP analysis and automated fill in a single operation to reduce design iterations

- Production proven – Fully qualified at TSMC for specific TSMC technology data